About RediStair®

Since 2006, thousands of RediStair® stringers have enhanced safety and efficiency for contractors while providing developers and owners with a durable and tasteful end-use product in commercial construction projects.

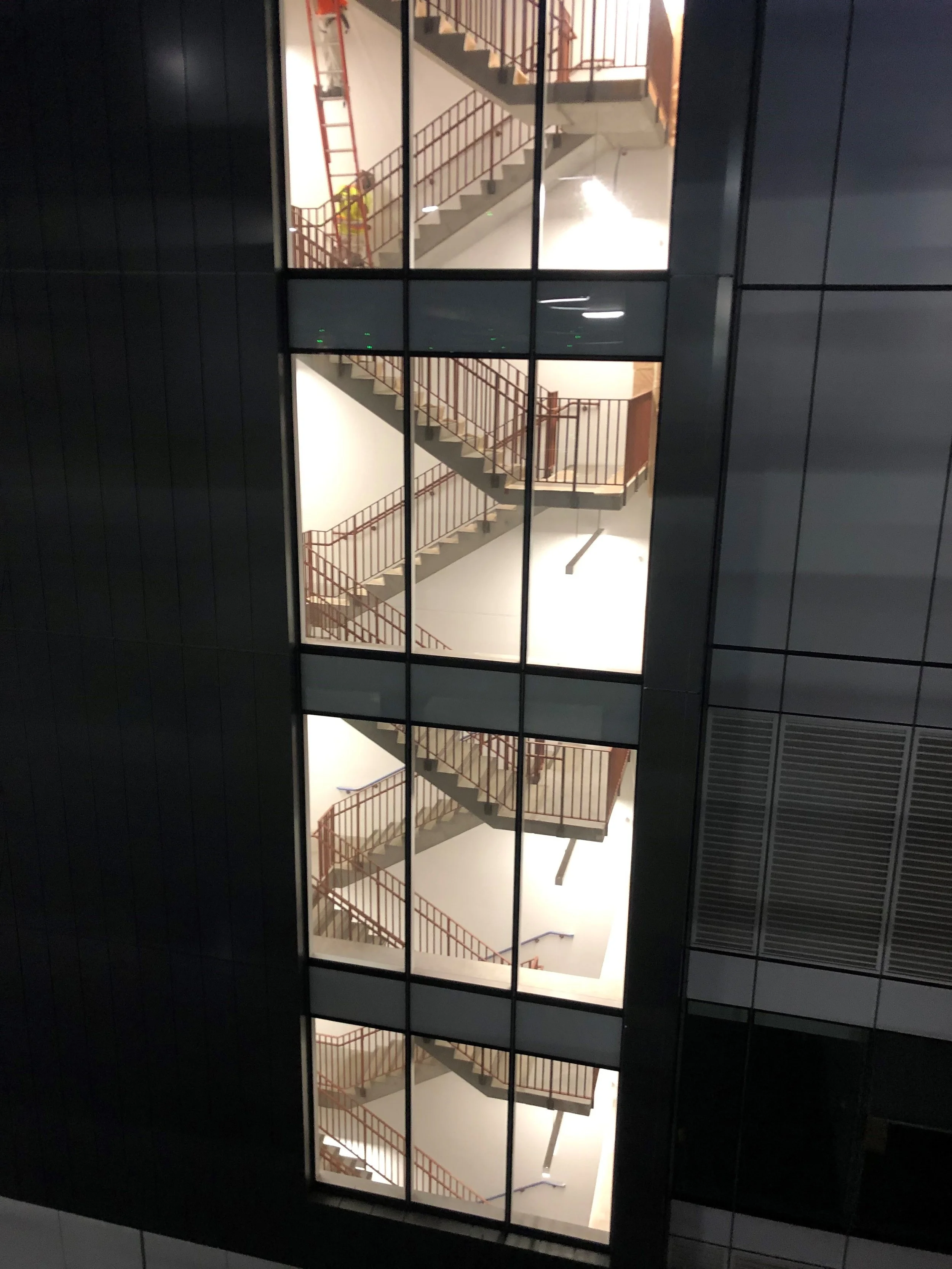

Designed to simplify the construction process, the RediStair® system installs as the building rises which reduces and/or eliminates the need for temporary stair systems and significantly improves jobsite safety and efficiency during the life of construction.

While easily integrated into most mild-reinforced and post-tensioned concrete structures, GC Solutions, LLC can often design and engineer connections to accommodate a variety of steel-frame structures. A comprehensive load analysis is performed for each “cantilevered truss” and the load conditions are provided to the engineer of record (EOR) for incorporation into the structural model.

RediStair® stringers can be delivered to the project on a “just-in-time” basis, or be delivered in advance and stored as organized stacks until they need to be installed; deliveries often align with the start of the decking operations for an elevated slab, resulting in immediate access to the live deck for all trades. In the event the concrete stairs are adjacent to core walls, and a gang form interferes with the elevated slab block-out, the setting of the RediStair® stringers may be delayed until the gang form clears the elevated slab. In circumstances where stairs are located within core walls, accommodations to the forming system may be required in the project’s pre-construction phase to allow crane access through the top of the forming system. GC Solutions, LLC will coordinate with your form designers, at no additional cost, to accommodate these sorts of specialized conditions.

RediStair® is the proprietary process that integrates precast concrete stair stringers and site-cast main and intermediate landings to form a “cantilevered truss” (unsupported landing). Once the RediStair® stringers are set and the site-cast landings reach design strength, all intermediate landing shoring may be removed, with the net effect being that the stair system is unsupported except at the connections to the structural slabs. The unsupported landings provide cost savings to the project through the elimination of both direct (support systems such as beams, columns, ledgers, pony walls, etc.) and indirect means (painting, fireproofing, maintenance of support systems, etc.). Within the RediStair® system, an unsupported landing is achieved when two stringers and one intermediate landing are configured in a 180° switchback orientation and span from one floor to the next. For configurations outside of these parameters, or where other complicating features exist, GC Solutions, LLC will design and engineer the additional stair support mechanisms, at no additional cost, to offer a complete bidder-design system.

FRP (Form, Reinforce, Place) activities at the main and intermediate landings, to include the setting of RediStair® stringers, stripping of formwork, and installation of temporary handrail, averages 16 total man-hours per floor-to-floor on projects with 30 or more RediStair® stringers. For projects with less than 30 stringers, the average is slightly higher at 18-20 total man-hours per floor-to-floor.

GC Solutions, LLC is actively looking to license NPCA and/or PCI certified precast plants across the United States. Contact us today to learn more about our licensing and certification process.

Bringing beauty, strength, and durability to your exit corridor, one step at a time!